Alkylyst was recently awarded an EPA P3 Student Design grant to continue the pursuit of catalytic perfection!

About

Meet the team behind Alkylyst!

History

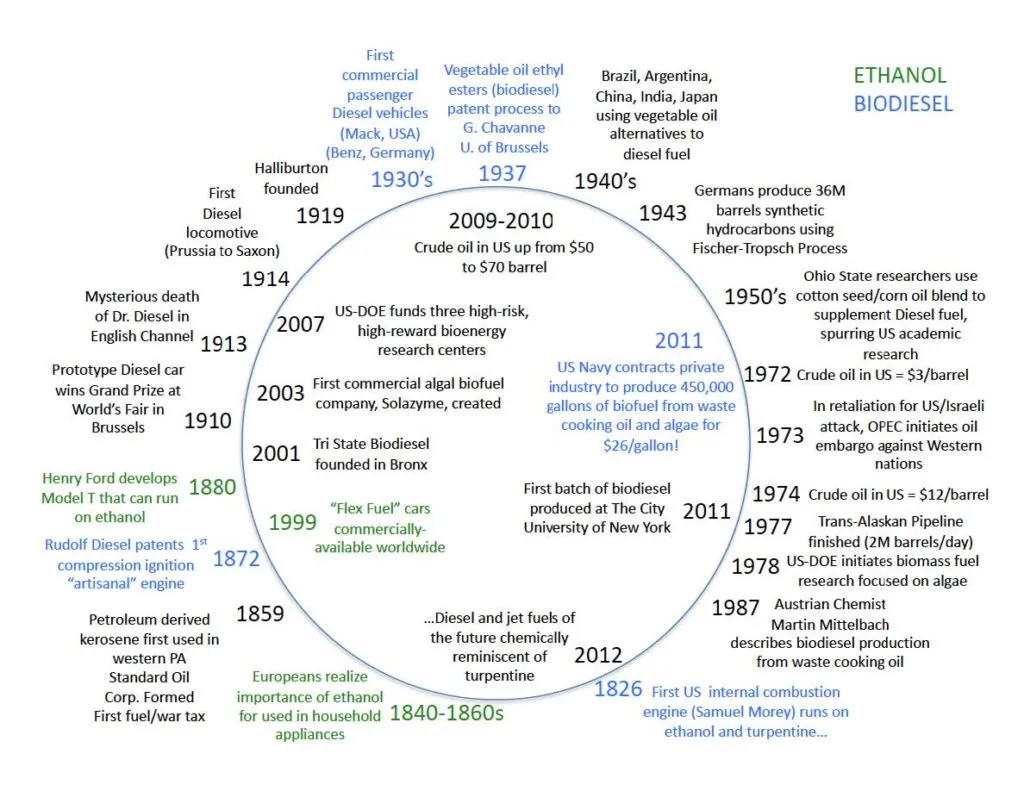

Learn about biodiesel and its positive impact!

Resources

Want to learn more, check out these additional sources!

The Blog

Stay up to date with the latest news!

Contact

Get in touch with the Alkylyst team!